Lubrication Solutions for Cement Plant Kilns

- Home

- E-Journal

- Post

Overview

- Proven intermittent spray technology to reduce lubricant consumption. Perfect for today’s synthetic/specialty gear lubricants.

- Provides reduced temperatures and wear rates of pinion and bull gears.

- Optional custom enclosures are available to provide “plug and play” installation.

- Increased output and production uptime.

- Reduced component cost with extended gear and pinion life.

- Optional spray nozzles available with push button clean out capabilities.

- Stand-alone design can be retrofitted with ease.

- Unmatched lubricant delivery accuracy.

- Programmable controller for simpler adjustability.

- Optional heated nozzles and enclosures for

cold temperature operating environments. - Afterblow to purge nozzles of grease.

- Reduced vibration and noise with synthetic/

specialty gear lubricants and controlled

intermittent spray. - The industry’s leading intermittent spray

lubrication system that monitors both

lubricant and air flow to the nozzle tip,

ensuring you have the right amount of

lubricant at the right time.

Overview

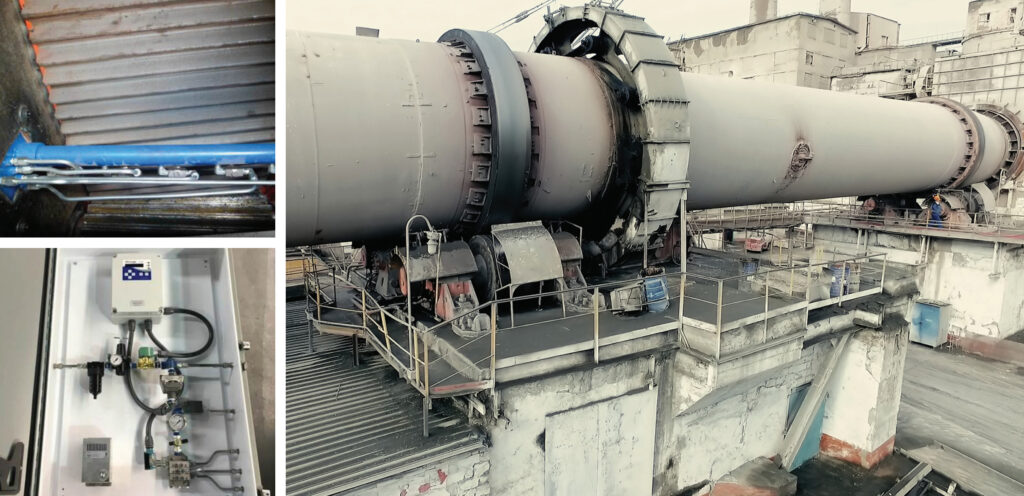

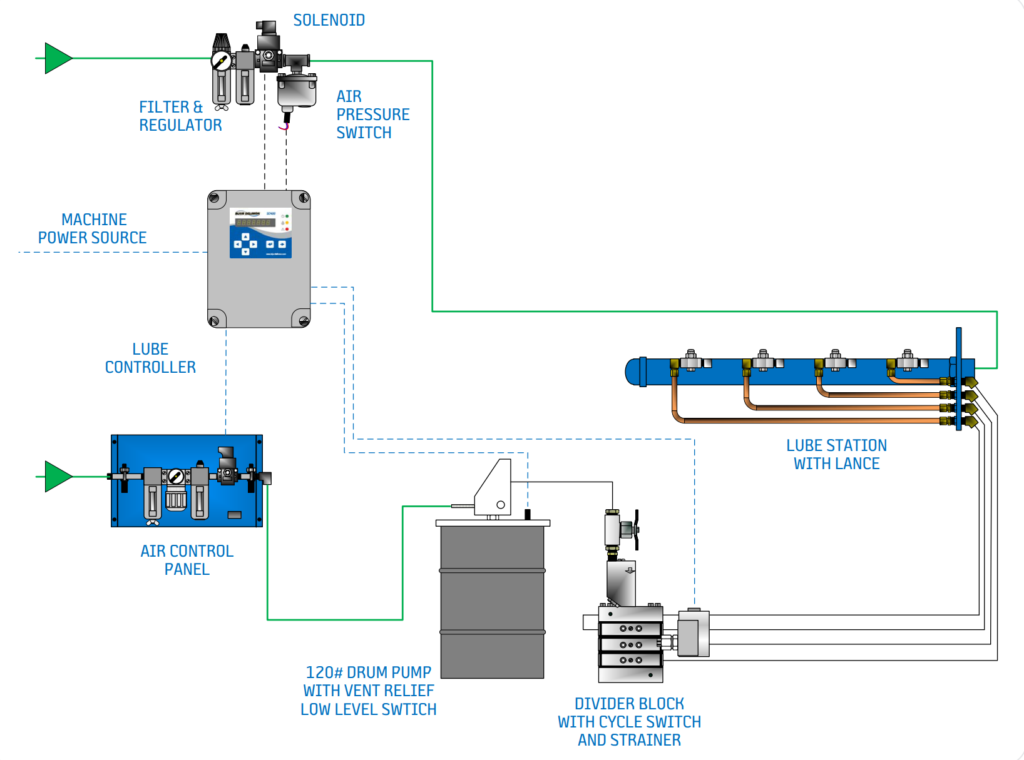

Bijur Delimon gear spray systems are used to lubricate large gear and pinion sets such as those founds in kilns. Each system includes an air operated pumping station, a measuring valve control panel, a spray nozzle lance, electrical controls and other optional equipment.

Gear face widths of 2” to 42” can be lubricated with nozzles and nozzle spacing designed accordingly. Because our gear spray systems operate intermittently, they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexiblity as well as fault monitoring and afterblow to purge nozzles.

GearSpray Elements

Bijur Delimon gear spray systems are used to lubricate large gear and pinion sets such as those found in kilns. Each system includes an air-operated pumping station, a measuring valve control panel, a spray nozzle lance, electrical controls, and other optional equipment.

Gear face widths of 2” to 42” can be lubricated with nozzles and nozzle spacing designed accordingly. Because our gear spray systems operate intermittently they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexibility as well as fault monitoring and after-blow to purge nozzles.

LIKE WHAT YOU READ? GIVE US A SHARE.

LinkedIn

Email

RECENT POSTS

SOCIAL MEDIA

SUBSCRIBE TO OUR NEWSLETTER

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

580 Davies Drive,

York, PA 17402

Tel: 717-885-2614

Email: hello@greasepoint.com

- 888-631-7638

- hello@greasepoint.com

- Serving the Mid-Atlantic Region

INDUSTRIES SERVED

OUR COMPANY

OUR PROMISE TO YOU

- Technical Excellence

- High-Quality Products

- Superior Customer Service