LINCOLN P653S TROUBLESHOOTING INSTRUCTIONS

Troubleshooting instructions for Low Level and Cycle Faults with Lincoln P653S

LINCOLN P653S TROUBLESHOOTING INSTRUCTIONS

Troubleshooting instructions for Low Level and Cycle Faults with Lincoln P653S

- Home

- Services

- Troubleshooting

- Lincoln P653S

About Lincoln P653S Pump

The fully integrated P 653S pump unit is an example of the Lincoln brand’s commitment to providing innovative, cost-effective solutions through industry-leading advances in technology. This next-generation, lower-cost pump package can be fitted with one of seven reservoir sizes and easily adapts to many applications. It also interfaces with telematics technology in today’s heavy equipment. A neutral switch allows mobile equipment to remain idling with pump power on, but the timer is deactivated, allowing manual lubrication functionality. All pumps include low-level and system fault alarms.

Simply mount the pump, connect the power and supply lines, and the system is ready for operation. The P653S pumps are available with different reservoir sizes from 4 to 100 liter.

Features & Benefits:

- Reduces operational risk compared to standard automatic lubrication

- Offers higher safety standards

- Brings lubrication system into compliance

Applications:

- Integration of major system components reduces operation costs

- Plug-and-play pump design for reduced installation time

- Neutral switch provides reduced grease consumption

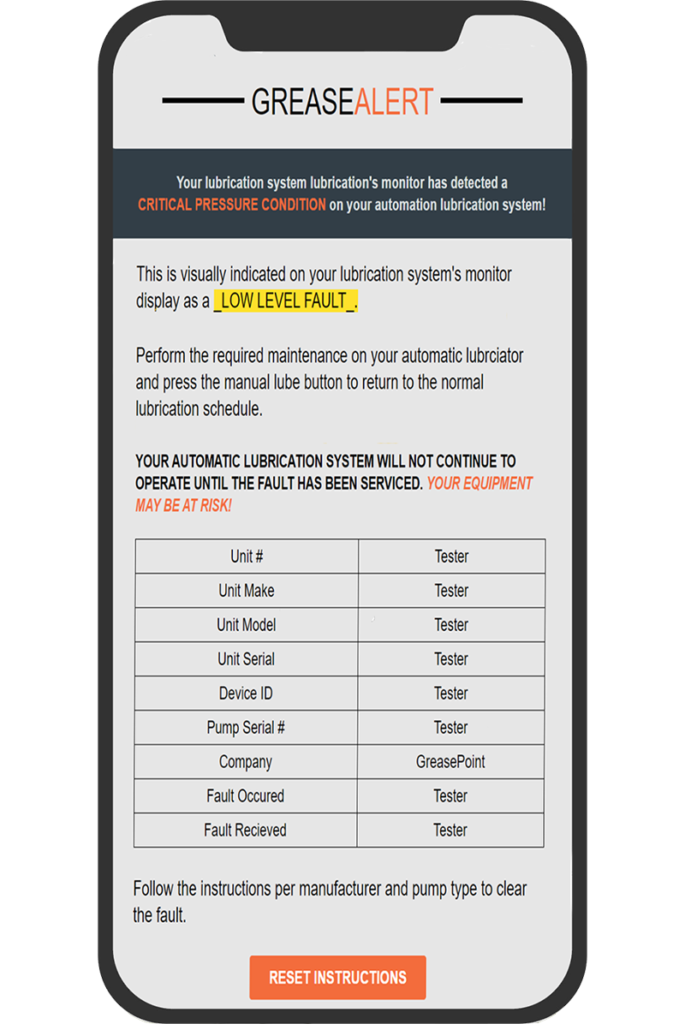

WHICH ARE YOU EXPERIENCING?

Select your error message to be taken to your specific troubleshooting instructions.

Low Level Fault

Level of lubricant in the reservoir is low and additional lubrication needs to be added.

Lube Fault

System fails to relieve pressure in the user-defined amount of time.

None of the Above What You're Experiencing?

The Lincoln P653S manual provides information on pump warnings, installation, setup, programming, troubleshooting, maintenance, and more. If you’d rather talk to a person than read a document, we’re always here to help!

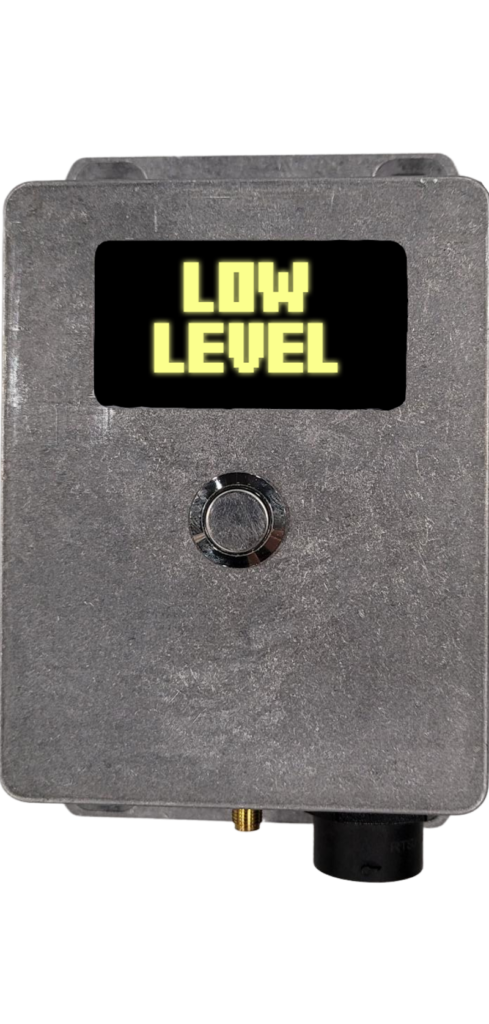

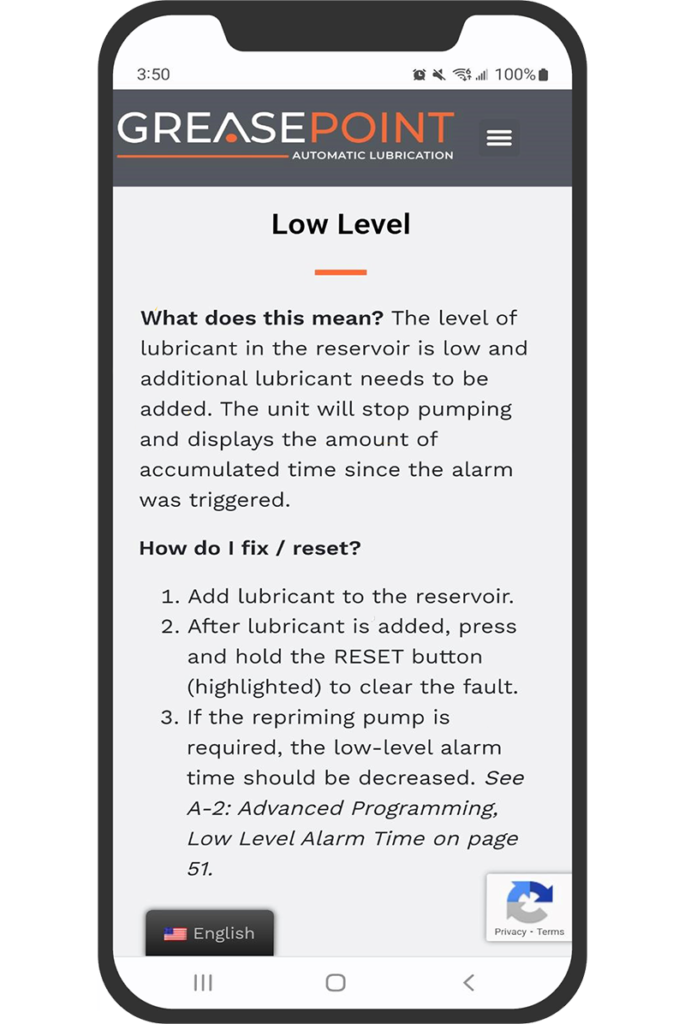

LOW LEVEL

What does this mean? Level of lubricant in reservoir is low and additional lubricant needs added.

How do I fix / reset?

- Fill pump reservoir from fill fitting on front of the reservoir or via ground level filling port if provided.

- Manually cycle the pump either from a remote run button in the cab, or via the push button on the pump cover circuit board (press and hold for 4 seconds).

- Verify the paddle turns, see the cycle pin moves on the primary valve – verify that the low level signal on GreasePoint’s monitor disappears.

LUBE FAULT

Solution: Check power supply and fuses.

Connect ignition or machine switch per electrical schematic on pages 28 and 29

Pump with follower – refill reservoir. Pump without follower – refill reservoir and push manual (green) button with an oildrop on it (pg. 18, Fig. 15) to initiate manual lube cycle.

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – air pockets, broken lines, connections leakage, worn pumping element, failed internal pressure switch or pressure transducer. Initiate manual lube cycle.

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – air pockets in lubrication line, connections leakage, grease consistency changed with low temperatures, failed end of line pressure switch or pressure transducer.

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – pump eccentric did not stop in a proper position, vent valve failed.

Push switch (pg. 18, Fig 15) to acknowledge and correct possible causes – restriction in lubrication line, grease consistency changed with low temperature, failed end of line pressure transducer or pressure switch.

Check and adjust setting of pressure transducer of failed pressure button (pg. 6, Fig 1). Verify you have pressure over 2000 PSI on your guage.

Not the product you were looking for?

ASK ABOUT REMOTE MONITORING

GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

- York, PA: 888-631-7638

- Charlotte, NC: 704-375-7704

- hello@greasepoint.com

- Service & repair shops in Pennsylvania and North Carolina