Get Back in Operations Quickly

With the help of their sister-brand, PennAir, GreasePoint offers inspection and repair services for your grease and oil pumps. Repair and replacement parts for Graco pumps can be purchased directly from our walk-in service counter. Simply visit PennAir’s factory trained service counter to get back in operations quickly.

Spare pumps can be purchased at a discounted rate to keep lubricants flowing while you wait.

Common Pump Problems

If we have the parts stocked, pumps can be turned around in a minimum of three (3) days. If parts need to be ordered, our goal is to have the repaired pump in 2-3 weeks. Replacement pumps can be purchased at a discounted rate to keep operations running smoothly while you wait for yours to be repaired.

Is the pump not cycling at all?

The most common cause of this is air motor failure. This repair is typically 2-4 hours upon receipt and start of repair.

Is the pump cycling but not putting out product?

The most common cause of this is check valve issues delivering the product out of the pump. This repair typically is 2-4 hours upon receipt and start of repair.

Is the product flow too slow at the end of the line?

There are two most common causes of this. The first being a check valve issue. The second is the pump or the delivery equipment is not adequately sized for the application. Contact your GreasePoint representative for help with this problem.

Tel: 800-455-6023

Email: hello@greasepoint.com

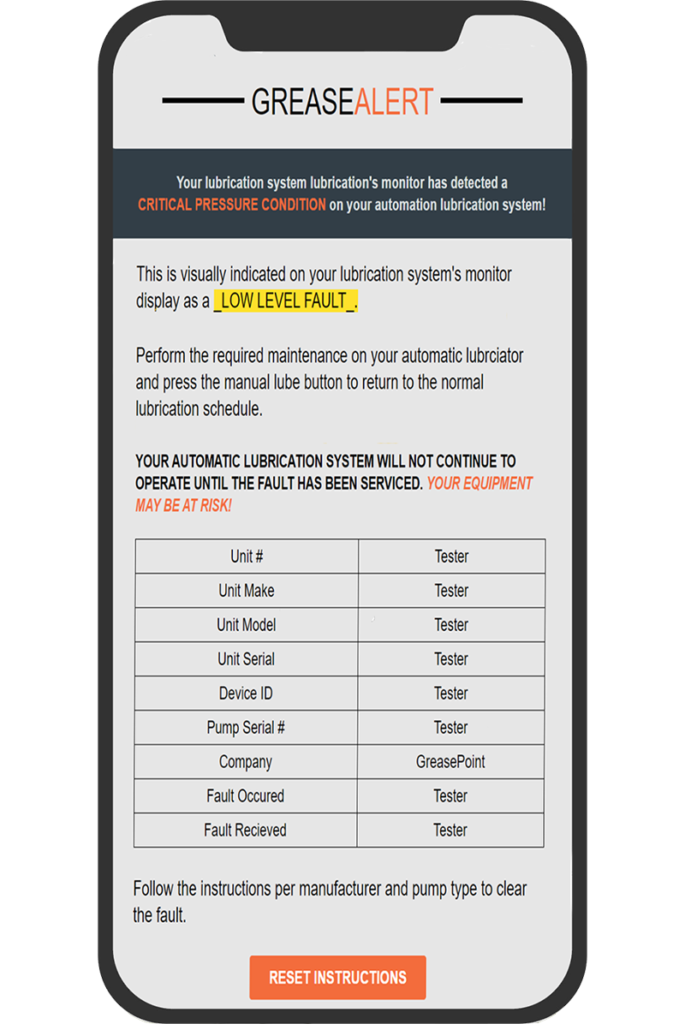

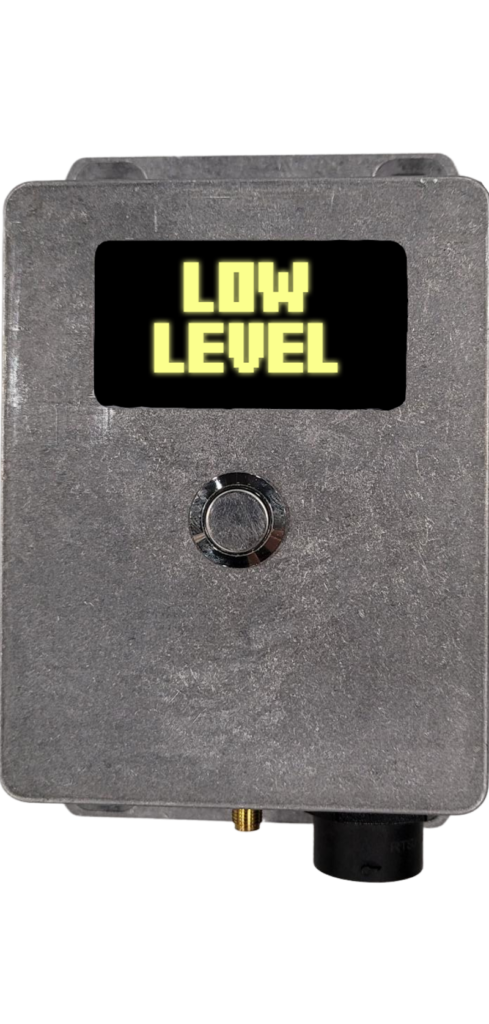

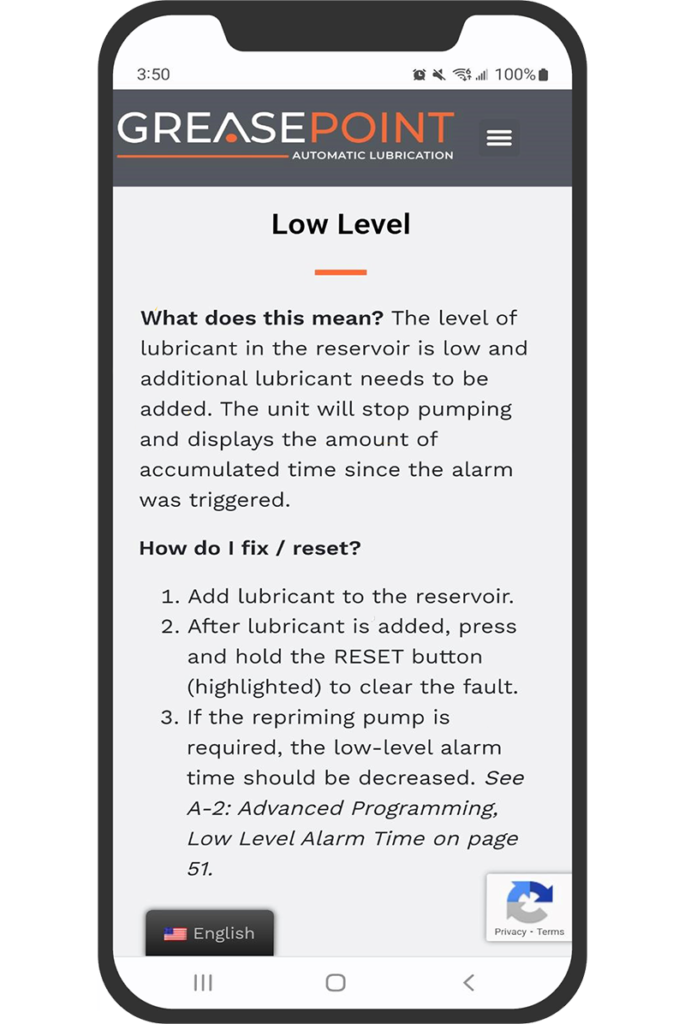

Looking to Clear Faults or for Troubleshooting Instructions?

Select your product to see instructions on how to clear fault messages on your automatic lubrication remote monitoring system.

ASK ABOUT REMOTE MONITORING

GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

WHAT'S THE RETURN ON INVESTMENT (ROI) OF AN AUTOMATIC LUBRICATION SYSTEM?

An investment in an automatic lubrication system for a typical piece of yellow iron, such as the Caterpillar 320 excavator, has an estimated ROI of as little as nine months. – ©Graco

- York, PA: 888-631-7638

- Charlotte, NC: 704-375-7704

- hello@greasepoint.com

- Service & repair shops in Pennsylvania and North Carolina