Protecting Your Municipal Fleet

- Home

- E-Journal

- Post

Overview

Whether you own or lease the equipment, proper maintenance pays off for everyone. The most common bearing failure is a damaged grease seal due to over pressurization while manually greasing. An automatic lubrication system minimizes pressure and provides metered grease to all points while your equipment is in operation. When all bearings are properly lubricated, you can expect an extended service life of your equipment and avoid unexpected costly repairs and downtime. Tired of crawling under or over equipment to service hard-to-reach lubrication points? Our automatic lubrication system takes care of the work for you.

Features & Benefits

- The system greases every point while your equipment is in operation and maintains a constant barrier at bushings preventing dust and dirt from entering wear surfaces.

- Increased safety as there is no need to crawl under or over equipment to service hard-to-reach lubrication points.

- Adding an automatic lubrication system increases equipment life by decreasing wear on vital components.

- Extend service life, reduce operative costs and lubricant costs.

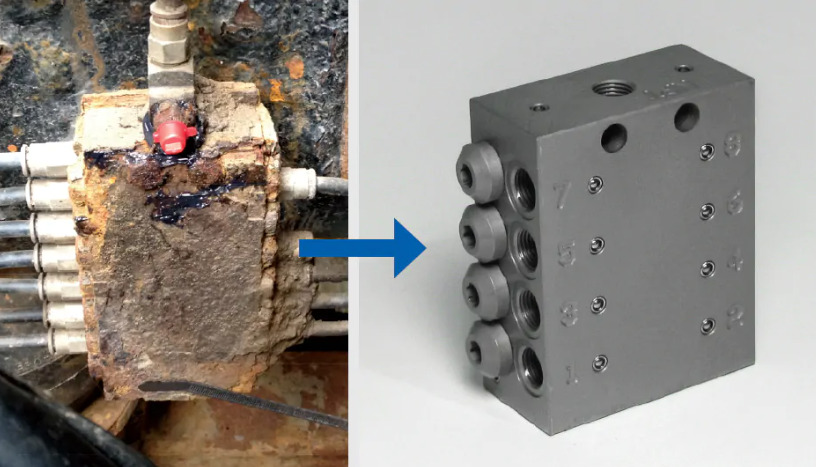

Don’t let your lube system become another corrosion target. Our valves come standard with a zinc nickel plating and are certified for the ISO 9227 Standard for salt spray testing.

Excessive power washing can remove grease at critical chassis points. Protect these points automatically.

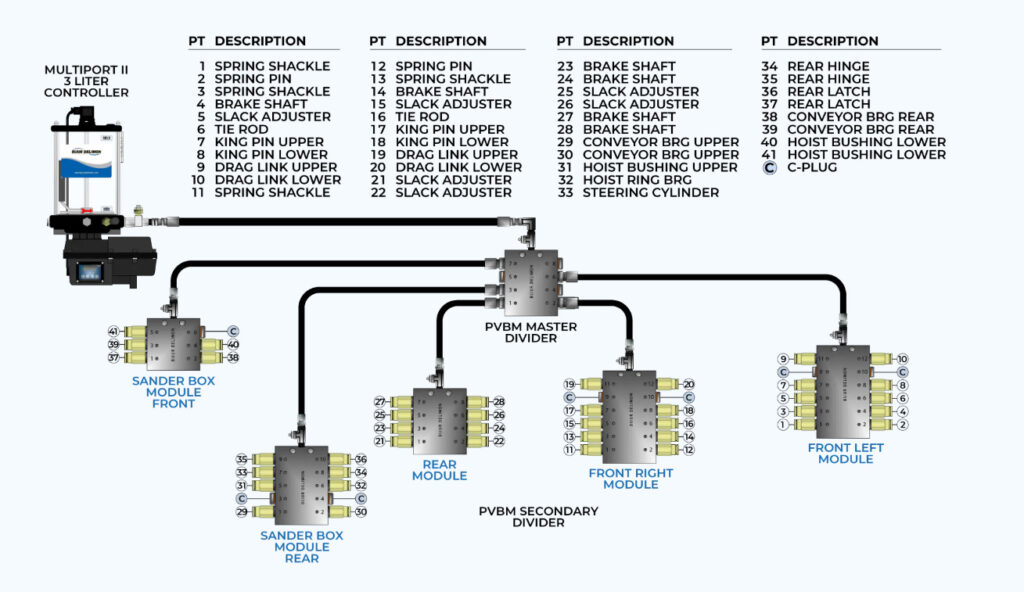

Municipal Equipment System Design

Multiport II Pump

The MultiPort II lubricator is an electrically driven multiple outlet lubrication unit designed primarily for use with progressive divider valve systems to accurately control the amount of grease and to monitor system performance via an integral controller. This pump features an economical built-in controller with improved water resistance and cold weather performance. With an IP69K rating, it is the perfect fit for on-road mobile applications.

PVMB Progressive Divider Valve

PVB Mobile Divider Valves accurately meter and dispense lubricant to as many as 20 outlet lines at operating pressures up to 3600 psi (248 bar). Output volumes are fixed at 0.17cc (0.01 cu. in.) per cycle but can be combined with other outlets by using appropriate fittings for larger outputs. Valves are available with cycle indicator pins to provide visual confirmation of system operation. In addition, the cycle pin can be fitted with a switch to provide electrical feedback to a system controller.

LIKE WHAT YOU READ? GIVE US A SHARE

LinkedIn

Email

RECENT POSTS

SOCIAL MEDIA

SUBSCRIBE TO OUR NEWSLETTER

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

- 888-631-7638

- hello@greasepoint.com

- Serving the Mid-Atlantic Region

INDUSTRIES SERVED

OUR COMPANY

OUR PROMISE TO YOU

- Technical Excellence

- High-Quality Products

- Superior Customer Service