Lincoln P203 Troubleshooting Instructions

Troubleshooting instructions for Low Level and Lube Fault for Lincoln’s P203

- Home

- Services

- Troubleshooting

- Lincoln P203

Lincoln P203 Troubleshooting Instructions

Troubleshooting instructions for Low Level and Lube Fault for Lincoln’s P203

- Home

- Services

- Troubleshooting

- Lincoln 203

About Lincoln P203

The P203 lubrication pump is versatile, compact and economical. It can supply up to 150 lubrication points, depending on the line length. It consists of a housing with integrated motor, reservoir with stirring paddle, pump element with pressure-relief valve, filling nipple and electrical connection parts. This powerful pump can drive up to three pump elements and can be equipped with a low-level control (with or without control board).

Optional control printed circuit boards with different operating settings

Range of reservoir types offered

For DC or AC applications

Variety of pumping elements for different output available

WHICH ARE YOU EXPERIENCING?

Select your error message to be taken to your specific trouble shooting instructions.

Low Level Fault

Level of lubricant in the reservoir is low and additional lubrication needs to be added.

Lube Fault

System fails to relieve pressure in the user-defined amount of time.

None of the Above What You're Experiencing?

The Lincoln P203 Manual provides information on safety, functions, technical data, installation, operation, and more. If you’d rather talk to a person than read a document, we’re always here to help!

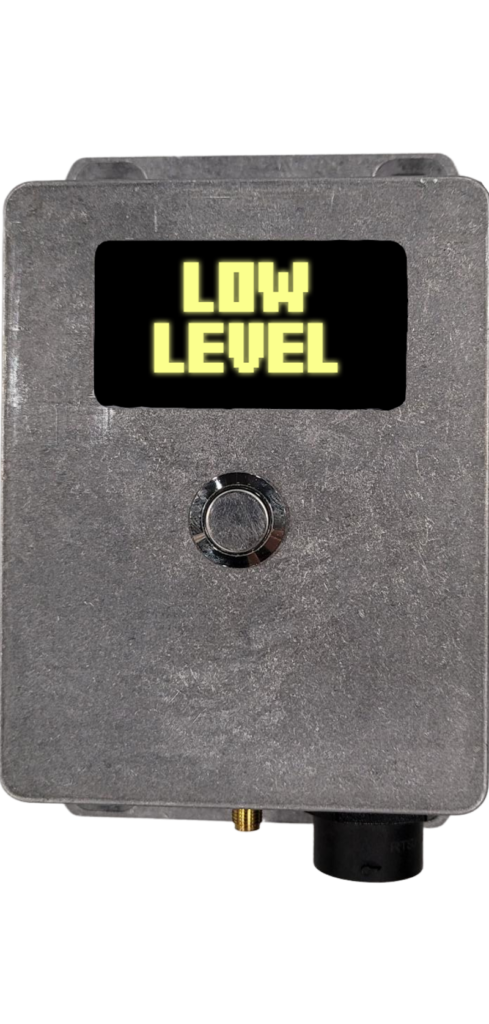

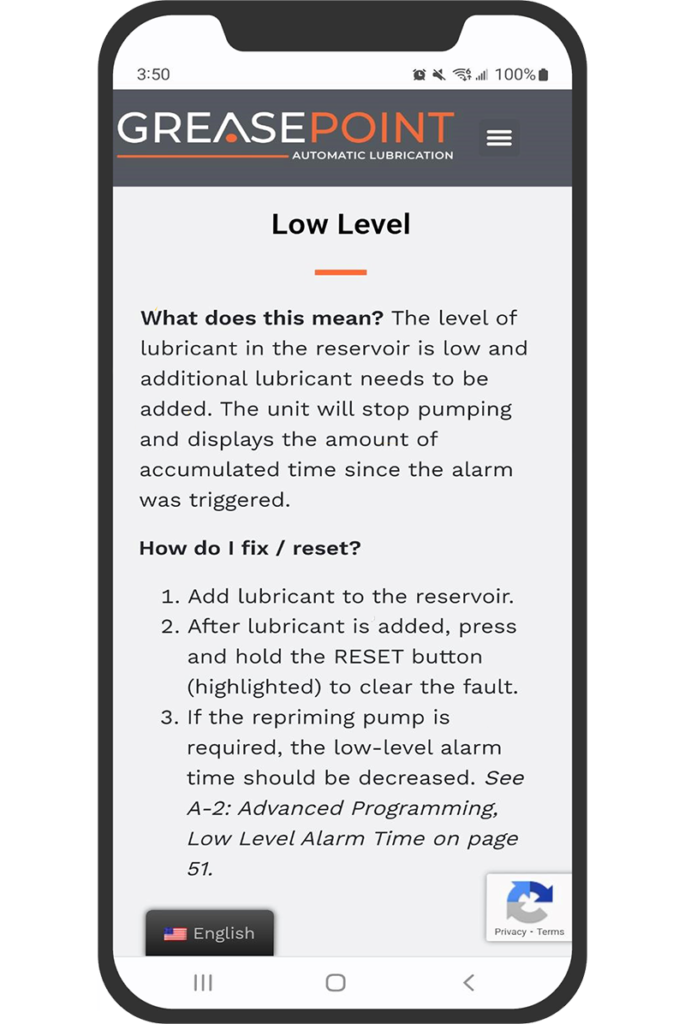

LOW LEVEL

What does this mean? Level of lubricant in reservoir is low and additional lubricant needs added.

How do I fix / reset?

- Fill pump reservoir from fill fitting on front of the reservoir or via ground level filling port if provided

- Manually cycle the lube pump either from a remote run button in the cab, or via the push button inside the pump cover on the circuit board – Press and hold for 4 seconds.

- Verify the paddle turns, see the cycle pin moves on primary valve – verify that the low level signal on GreaseMon disappears.

Lube Fault

Select your error message to view troubleshooting instructions.

There are two (2) probable causes of this:

- Not receiving voltage: Check fuses, timer and electrical supply. Check the electrical supply to the pump. If the pump receives no current, trace the electrical source and repair.

- Blocked pump cam: Replace the pump motor if no blockage is identified.

There are two (2) probable causes of this:

- Air pocket at pump element inlet: Disconnect the main delivery hose from the pump outlet. Run the pump until solid grease (no bubbles) flows from the outlet. If solid grease does not discharge after 20 minutes of operation, the pump inlet is blocked with a contaminant. NOTE: Depending on operating temperatures and types of grease, it may require 10 minutes to achieve full volume at the outlet.

- Blocked pump outlet: Remove the pump element from the pump body and inspect the suction inlet port for foreign particles. Remove any particles found. Reassemble the pump and element and cycle the pump. If the pump element does not discharge grease, replace the pump element.

Probable cause is no grease: fill the reservoir to the “max” level and press the manual reset button.

Probable cause, blockage in the metering valves, hose, tube, or connected component:

- Switch the pump on and loosen each outlet in the primary valve one at a time. The blocked outlet will start to discharge to its secondary valve. Repeat the process of loosening each outlet one at a time until the blocked feed line is detected.

- Retighten all outlets.

- Repair the component blockage if found.

- If a metering valve is creating the blockage, replace the metering valve.

Probable cause, blockage in the metering valves, hose, tube, or connected component:

- Switch the pump on and loosen each outlet in the primary valve one at a time. The blocked outlet will start to discharge to its secondary valve. Repeat the process of loosening each outlet one at a time until the blocked feed line is detected.

- Retighten all outlets.

- Repair the component blockage if found.

- If a metering valve is creating the blockage, replace the metering valve.

Replace the complete hose or tube. Or, if the tube is broken, cut the tube at break and repair using tube union (part #244058).

If the hose is broken, cut ends at the break and install new reusable hose ends (part #246002) and screw into a 1/8″ NPT female connector (part #67063).

Not the pump you were looking for?

ASK ABOUT REMOTE MONITORING

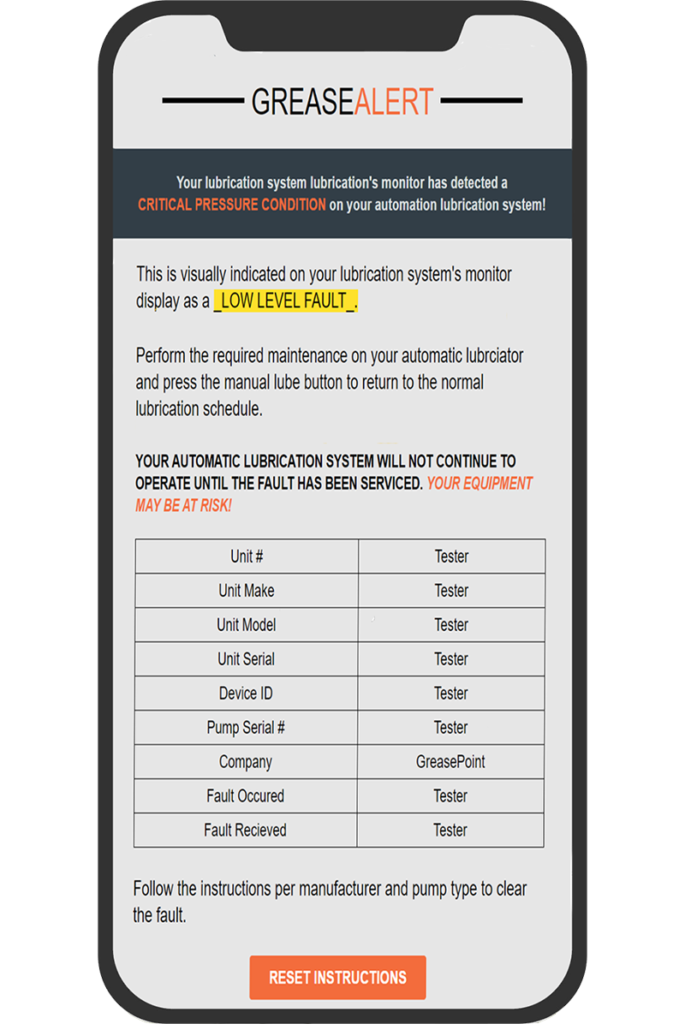

GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

- York, PA: 888-631-7638

- Charlotte, NC: 704-375-7704

- hello@greasepoint.com

- Service & repair shops in Pennsylvania and North Carolina