GRACO GLC 2200 CONTROLLER TROUBLESHOOTING INSTRUCTIONS

Troubleshooting instructions for Low Level, Pressure Warnings, Cycle Fault, and System Fault with Graco’s GLC 2200 Series Controller.

- Home

- Services

- Troubleshooting

- Graco GLC 2200

About Graco GLC 2200 Series Controller

You spend a lot on your equipment. The GLC 2200 controller helps protect components by alerting you to lube events, failures and low lubrication levels. You have peace of mind knowing your investment is protected.

Easy to mount without having to open up the control box

LEDs let you know what your system is doing at a glance

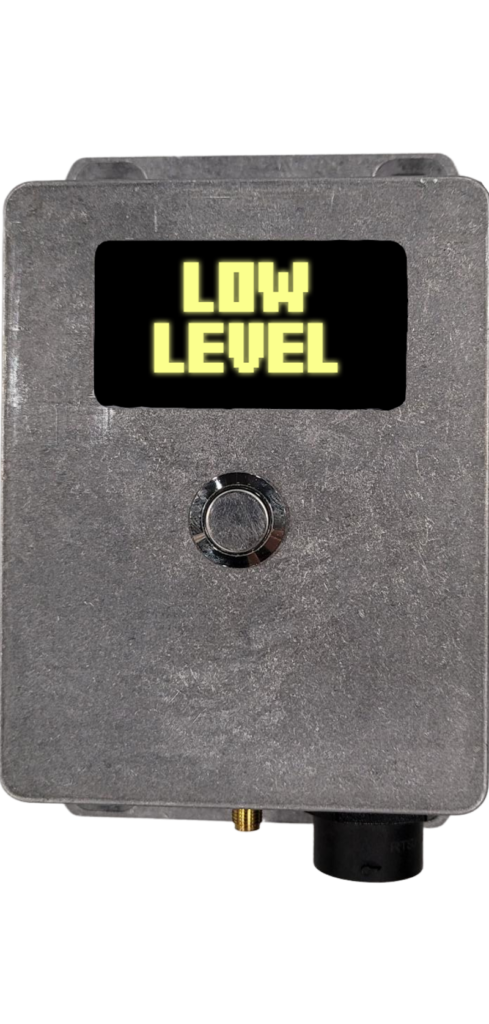

Easy to read digital display makes it simple to program and monitor your equipment

In-cab visual and audible alarms let the operator know your equipment needs attention. Or set up a remote alarm to alert service or maintenance staff

Simple icon-based push buttons make programming easy

Color coded wiring harness with flying leads and easy to follow wiring diagrams makes installations efficient

WHICH ARE YOU EXPERIENCING?

Select your error message to be taken to your specific trouble shooting instructions.

Er: LL = Low Level Fault

Level of lubricant in the reservoir is low and additional lubrication needs to be added.

Er: Pr = Pressure Warning

System fails to relieve pressure in the user-defined amount of time.

Er: CY = Cycle Fault

Indicates a cycle was not completed in the user-defined amount of time.

Er: SY = System Fault

Indicates a system error has occurred.

None of the Above What You're Experiencing?

The Graco GLC 2200 manual provides information on installation, setup, operation, programming, troubleshooting, and more. If you’d rather talk to a person than read, we’re always here to help!

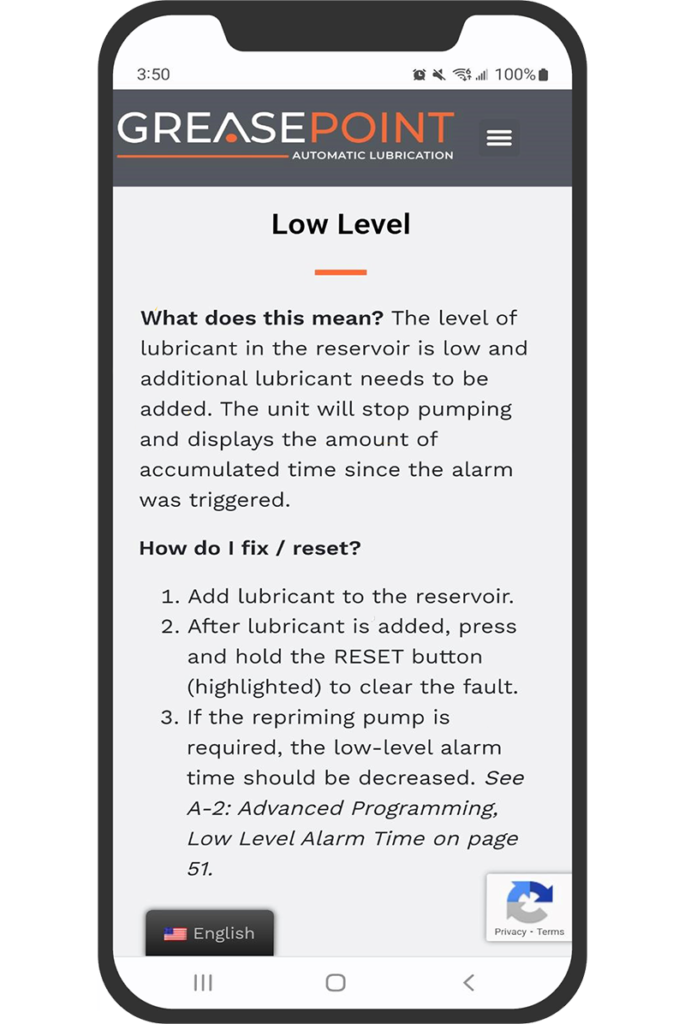

Er: LL - LOW LEVEL

What does this mean? Level of lubricant in reservoir is low and additional lubricant needs added.

How do I fix / reset? Refill lubricant reservoir and if level fault occurs unexpectedly verify the wiring and programming setup.

Er: Pr - PRESSURE WARNING

What does this mean? System fails to relieve pressure in the user-defined amount of time.

How do I fix / reset?

- Inspect lubrication system for broken or plugged items.

- Confirm pump is operating correctly.

- Confirm vent valve is operating correctly.

- Inspect wiring and switch.

- Confirm that sufficient backup time was programmed for environment conditions (e.g., slower system response in cold temperatures.)

- Verify programming.

Er: CY - CYCLE FAULT

What does this mean? Backup time expired prior to receiving programmed number of cycle counts.

How do I fix / reset?

- Inspect lubrication system for broken or plugged lines.

- Confirm pump is operating correctly.

- Inspect wiring and switch.

- Confirm that sufficient backup time was programmed for environment conditions (e.g., slower system response in cold temperatures).

- Verify programming.

Er: SY - System Fault

What does this mean? An internal error has occurred.

How do I fix / reset?

- Cycle power

- If the system error persists, the controller may need to be replaced.

Not the pump you were looking for?

LEARN MORE ABOUT GRACO

Graco designs and manufactures fluid handling and automatic lubrication equipment specifically for off-road mobile, on-road mobile and in-plant applications.

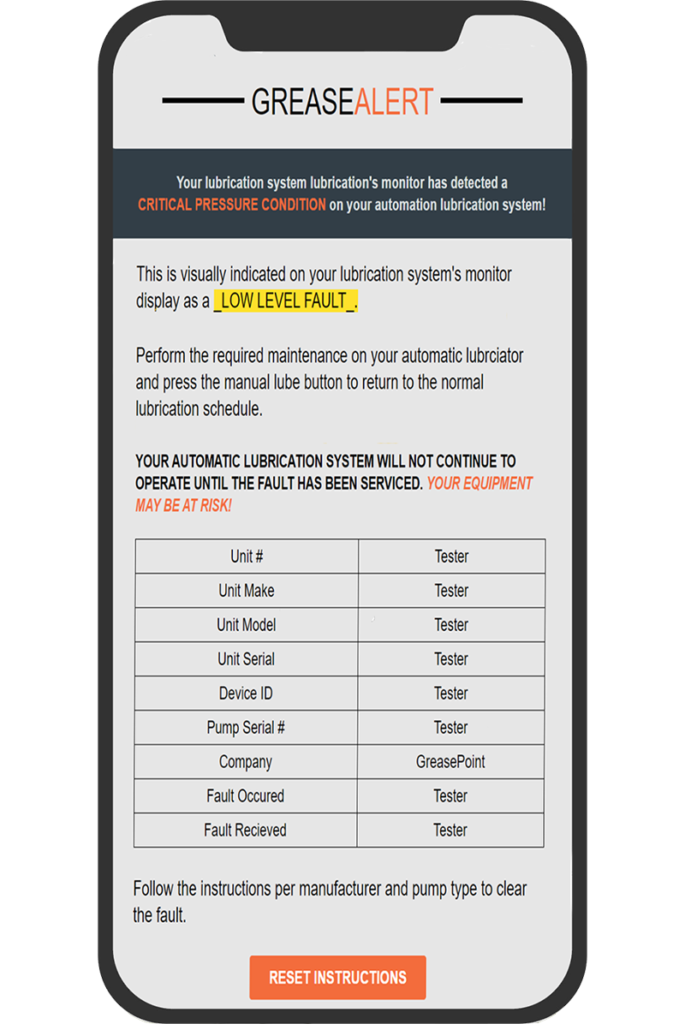

ASK ABOUT REMOTE MONITORING

Compatible with the Graco GLC 2200 Controller, GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

- York, PA: 888-631-7638

- Charlotte, NC: 704-375-7704

- hello@greasepoint.com

- Service & repair shops in Pennsylvania and North Carolina