Graco’s G3 Pump Series

For demanding lubrication applications, professionals turn to Graco’s durable and reliable G3™ automatic grease & oil pumps. These pumps handle changing temperatures and challenging grease types with ease.

- Home

- E-Journal

- Graco G3 Pump Series

Why G3 is Better

Two in One Design Does More!

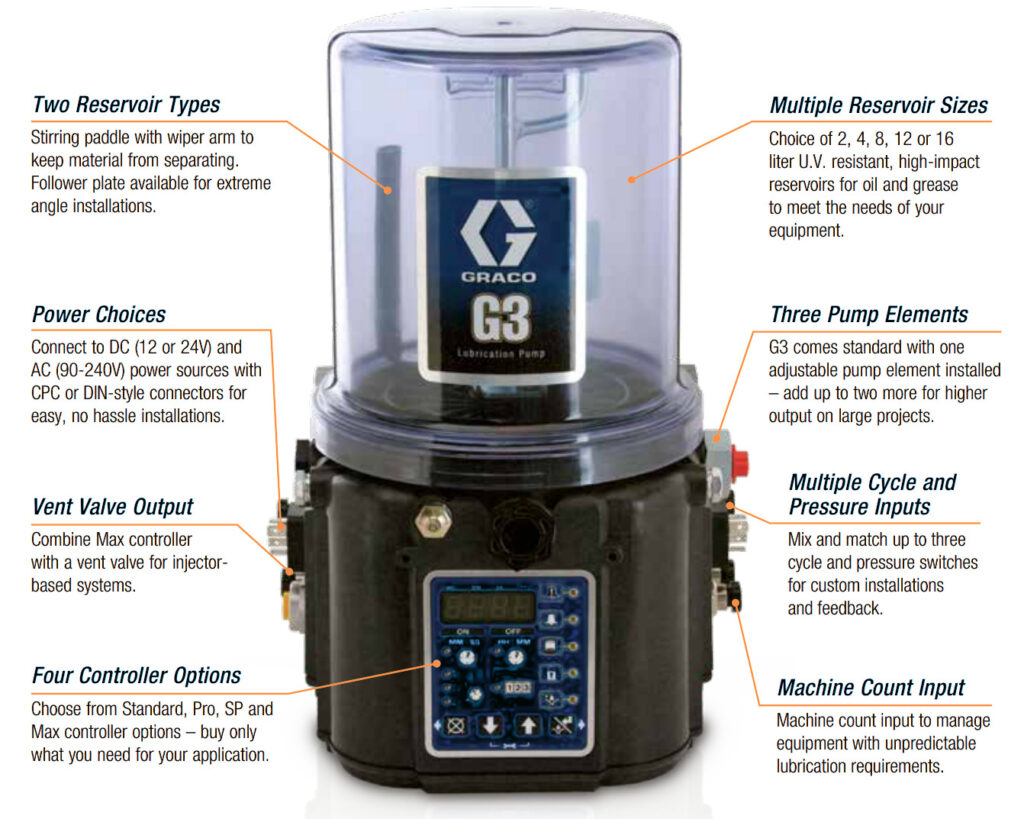

G3’s flexible design works with injector-based and series progressive systems. A cost-effective pump designed to serve multiple markets and applications.

Options that Fit Your Business

Three controllers to choose from with multiple zone and feedback options. Includes one adjustable pump element–standard, plus room for two more. Multiple reservoir choices and more! The ultimate in flexibility–for a high value, custom fit on your application.

Built-in Tools to Help You Succeed

Work faster and smarter with Graco’s exclusive Data Management System (DMS™). Find out exactly how your lubrication system is performing and how well it’s lubricated. Tracks history, provides data protection, upload or download data using a simple USB flash drive.

World Wide Support with Experienced Professionals

Graco wants to help you become more successful. Our staff of professional engineers, designers, field experts and customer service representatives are at your service. We invite you to call on us to partner in your next project.

Take a Look Inside - We Think You'll Like What You see

Designed from the inside-out for longer lasting performance and reliability. G3 meets changing temperatures, challenging installation requirements and changing grease types head-on. Graco’s newest electric pump delivers high performance results in real world application conditions.

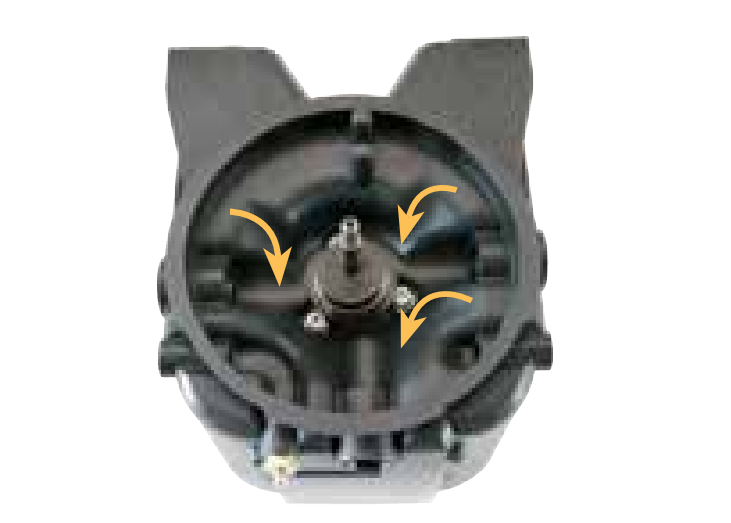

Advanced Flow Dynamics

Specially contoured base funnels grease directly to the pump inlet to significantly reduce stagnant flow areas where soaps and grease fillers can accumulate.

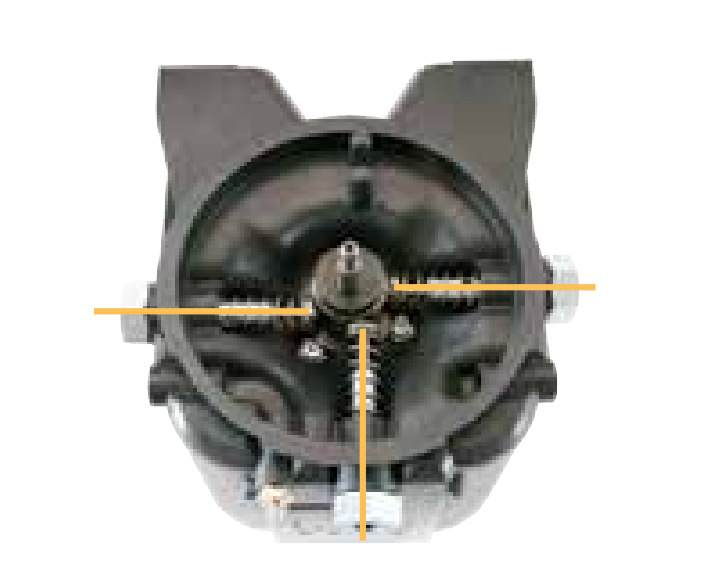

Adjustable Stroke Pump

With G3, adjustability comes standard! Eliminate the need to purchase additional fixed output elements or high-priced adjustable elements.

Load Minimizing Drive

Each G3 piston pump element is offset from the main motor shaft resulting in less stress on the motor and internal components.

Versatile, Hard-working Pump

Data Management System (DMS)

- Simple data transfer to your PC via USB flash drive for further analysis using Excel® or Notepad®

- Provides performance history for lube system events, such as cycle detection, error logs and allows a quick check of lubrication performance to meet your system requirements.

- Preferred lube cycle program can be stored and transferred to other G3 pumps in your fleet for quick and accurate repeatability.

- Provides you the comfort and security in knowing your pump is being properly maintained and your lube system is protecting your valuable asset.

Auto-fill Shutoff (AFSO)

- Available on G3 Standard, Pro and Max

- Eliminates over- or under-filling

- Completely fill the reservoir every time while avoiding costly spills

- Does not require power to operate

- Complies with stringent mining regulations where a system must be powered down during fluid refilling

- Compatible with fast-fill-equipped lubrication trucks

- Reservoir Full Visual Indication

- Valve Plate activates a poppet valve, which cuts off grease flow into the reservoir

Control Your Business

G3 Standard

- No internal controller – use with separate or existing machine control for a low-cost solution

- Capable of sending a low-level signal to your external controller or PLC

G3 Pro

- Built-in controller with selectable pump on/pump off timer

- Low level indicator provides low warning and shut-down alarm

- Manual run initiates lube cycle on-demand (remote option also available)

- Password protection safeguards settings

- Pre-lube function can initiate lube cycle on start-up

G3 Max

- Built-in controller with selectable pump on/pump off timer

- Low level indicator provides low warning and shut-down alarm

- Manual run initiates lube cycle on-demand (remote option also available)

- Password protection safeguards

- Pre-lube function can initiate lube cycle on start-up

- Up to three pressure or cycle switch inputs to ensure proper lubrication cycles

- Mix/match cycle and pressure switches for custom installations and feedback

- Machine count input – ideally suited for inconsistently used equipment

- Fault indication to external alarms

- Optional Data Management System™ (DMS)

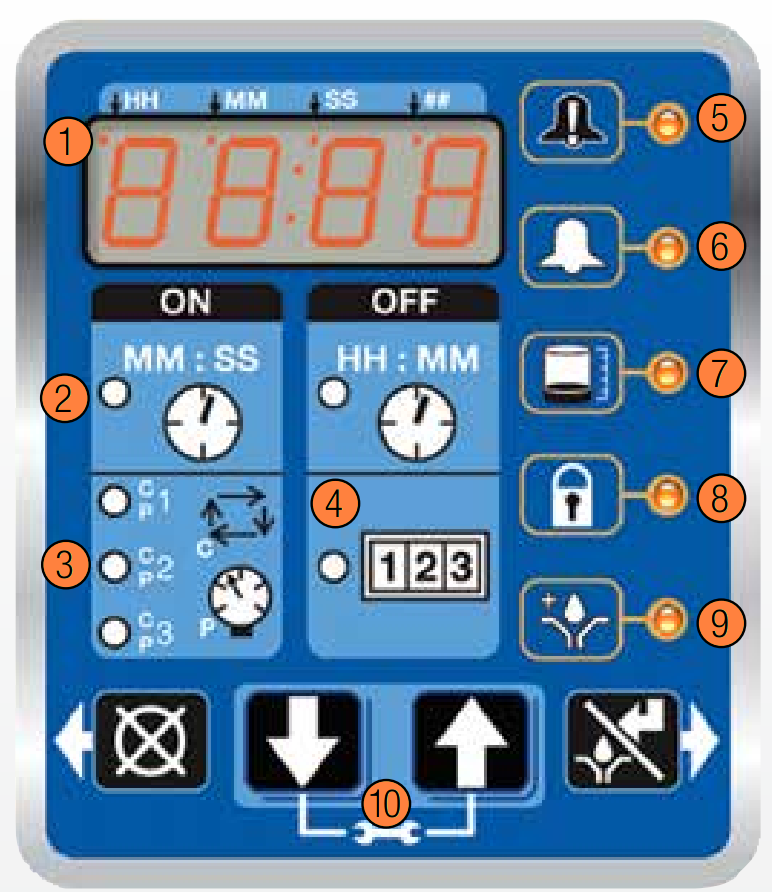

Check Out the Full-featured G3 Max

- Easy-to-read LED display

- Clearly identified pump on/off indication

- Monitoring of up to three independent zones

- Programmable machine count feature

- Alarm signal of lube system shutdown

- Warning signal prior to lube system shutdown

- Low level indication

- Password protected access to control

- Pre-lube capability

- Easy-to-use navigation keys

Technical Specs

- Maximum Working Pressure: 5,100 psi (352 bar)

- Power: 12 VCD, 24 VDC, 90-240 VAC

- Operating Temperature: -40 to 158º F (-40 to 70º C) depending on lubricant used

- Reservoir Size: 2, 4, 8, 12 or 16 liter

- Adjustable Pump Output Per Element Per Minute: 0.12 in, 0.18 in, 0.25 in (2 cm, 3 cm, 4 cm)

- Lube Type: Oil or Grease, up to NLGI #2

- Certifications/Ratings: CE, ETL*, IP69K

*Conforms to UL 73, certified to CSA 22.2 No. 68-09

LIKE WHAT YOU READ? GIVE US A SHARE!

LinkedIn

Email

RECENT POSTS

SOCIAL MEDIA

SUBSCRIBE TO OUR NEWSLETTER

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

- 888-631-7638

- hello@greasepoint.com

- Serving the Mid-Atlantic Region

INDUSTRIES SERVED

OUR COMPANY

OUR PROMISE TO YOU

- Technical Excellence

- High-Quality Products

- Superior Customer Service