GreaseAlert: Automatic Lubrication Remote Monitoring System

Monitor your lubrication systems with instant feedback on performance.

- Home

- Services

- Remote Monitoring

What is it?

Compatible with Many Systems

Suitable for Any Application

Communicates with You

What is it?

Compatible with Many Systems

Suitable for Any Application

Communicates with You

Manufacturing

Speed, flexibility

Construction

Heavy performance

Fleets

Maximize productivity

Vehicle Services

Efficient, effective

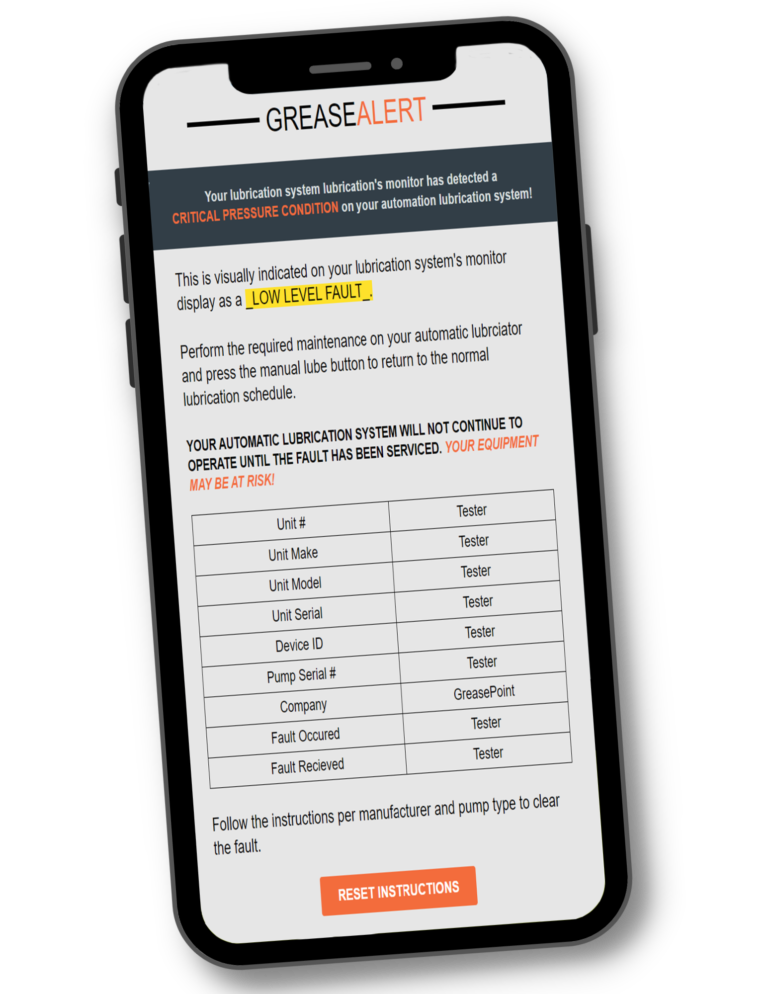

TO RESET

View Alert Email

The issue your system(s) are experiencing will be highlighted in yellow. Click 'Reset Instructions'

GreaseAlert.com

Visit GreaseAlert.com and select reset instructions for your pump.

Select the Problem

Click on which issue your experiencing to be taken to the easy to follow reset and troubleshooting instructions.

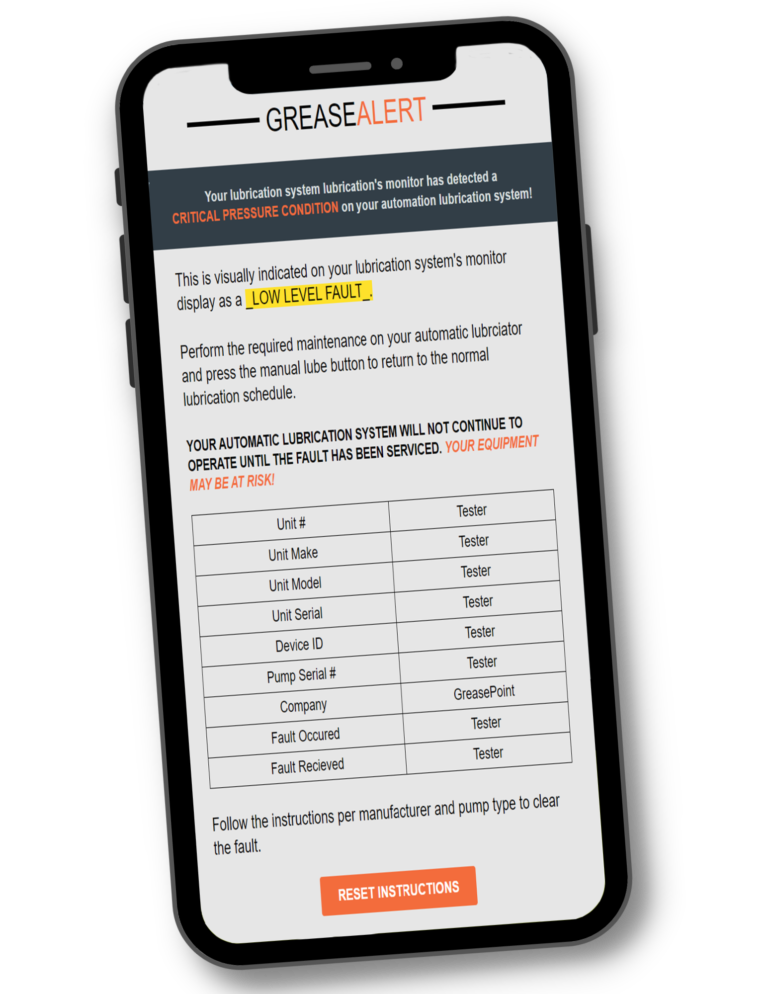

TO RESET

View Alert Email

The issue your system(s) are experiencing will be highlighted in yellow. Click 'Reset Instructions'

GreaseAlert.com

Visit GreaseAlert.com and select reset instructions for your pump.

Select the Problem

Click on which issue your experiencing to be taken to the easy to follow reset and torubleshooting instructions.

TECH SPECS

- Communicates via WiFi or Cellular Data

- Power Input (12 – 24 VDC only – no AC)

- Enclosure Rating – IP65K

- Box Size 4.6” wide x 3.5” tall x 1.5” deep

- Antenna included with unit

- Amphenol connector - 12 pin

- 6-foot color coded wire harness available

- AC to DC power conversion enclosure available

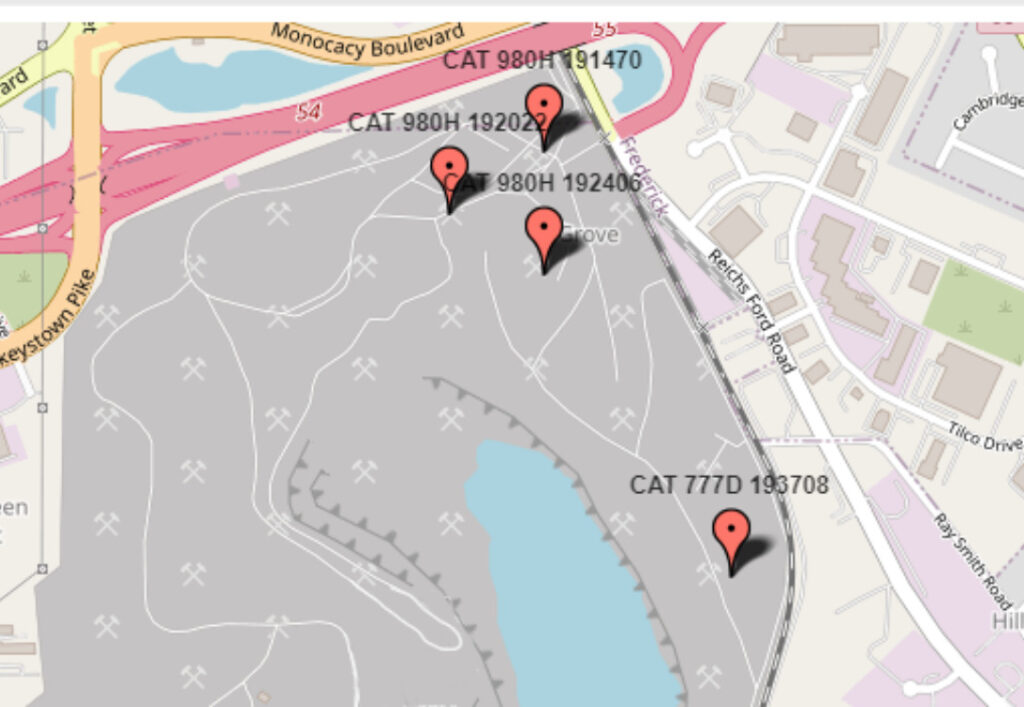

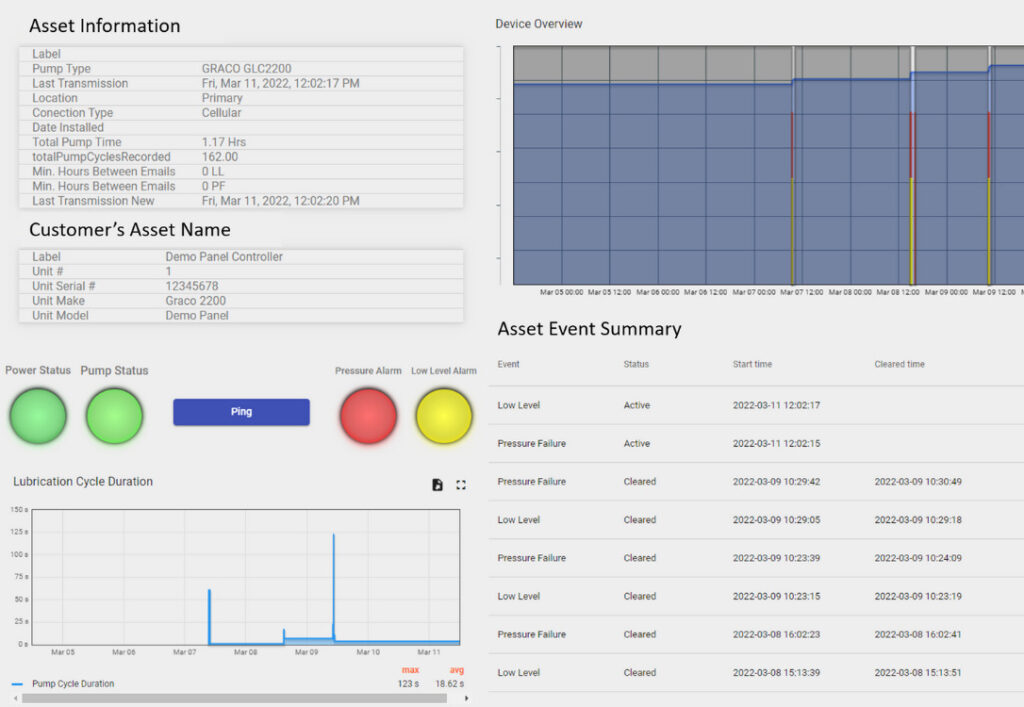

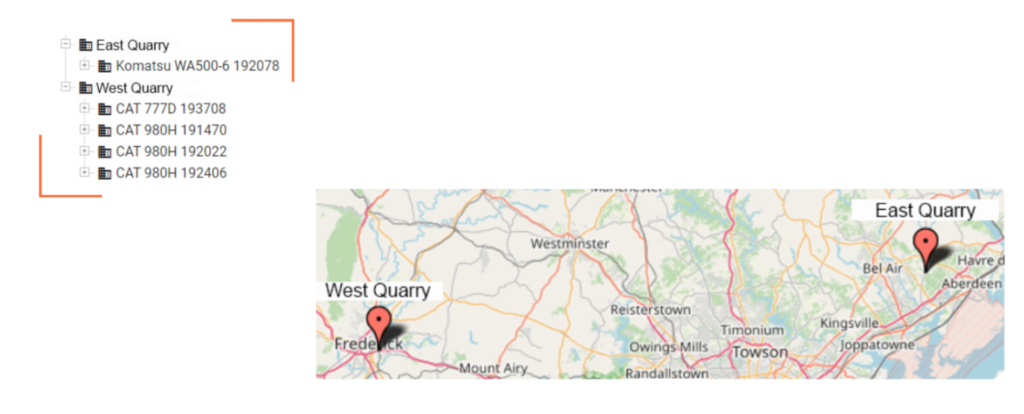

INTERACTIVE LIVE WEBSITE DASHBOARD

MONITOR MULTIPLE SITES & MULTIPLE ASSETS PER SITE

We believe in making it easier for organizations to work and grow on an international scale.

WHAT'S THE RETURN ON INVESTMENT (ROI) OF AN AUTOMATIC LUBRICATION SYSTEM?

An investment in an automatic lubrication system for a typical piece of yellow iron, such as the Caterpillar 320 excavator, has an estimated ROI of as little as nine months. – ©Graco