GRACO G3 AUTOMATIC GREASE & OIL PUMP TROUBLESHOOTING INSTRUCTIONS

Troubleshooting instructions for Low Level, Pressure Warnings and Cycle Fault with Graco’s G3 pump series.

- Home

- Services

- Troubleshooting

- Graco G3

GRACO G3 AUTOMATIC GREASE & OIL PUMP TROUBLESHOOTING INSTRUCTIONS

Troubleshooting instructions for Low Level, Pressure Warnings and Cycle Fault with Graco’s G3 pump series.

- Home

- Services

- Troubleshooting

- Graco G3

Graco G3 Grease & Oil Pump

Temperature changes, changing grease types, and challenging installation requirements are no problem for the G3 electric lubrication pump. With its flexible design, including adjustable pump elements and an ability to work with both injector-based and series progressive systems, G3 is a rugged, cost-effective pump which will extend machinery life, reduce operating costs, and increase productivity.

Designed for long-lasting performance and reliability

Able to standup to harsh working conditions and high wear-and-tear environments.

Cost-effective lube pumps provide versatility for all applications.

Extend equipment life with these hard-working automatic grease and oil pumps.

WHICH ARE YOU EXPERIENCING?

Select your error message to be taken to your specific trouble shooting instructions.

Er: LL = Low Level Fault

Level of lubricant in the reservoir is low and additional lubrication needs to be added.

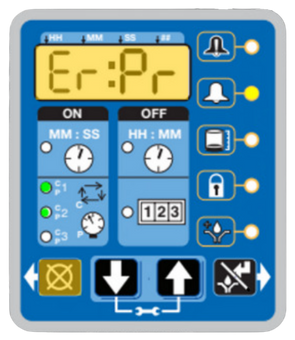

Er: Pr = Pressure Warning

System fails to relieve pressure in the user-defined amount of time.

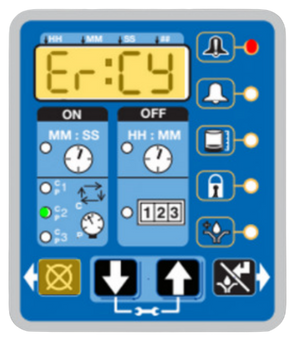

Er: Cy = Cycle Fault

Indicates a cycle was not completed in the user-defined amount of time.

None of the Above What You're Experiencing?

The Graco G3 Manual provides information on pump warnings, installation, setup, programming, troubleshooting, maintenance, and more. If you’d rather talk to a person than read a document, we’re always here to help!

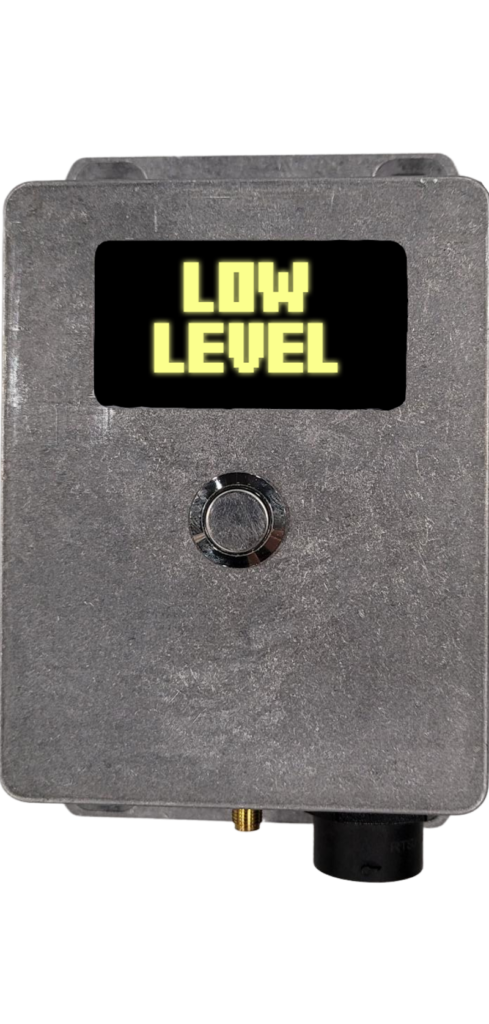

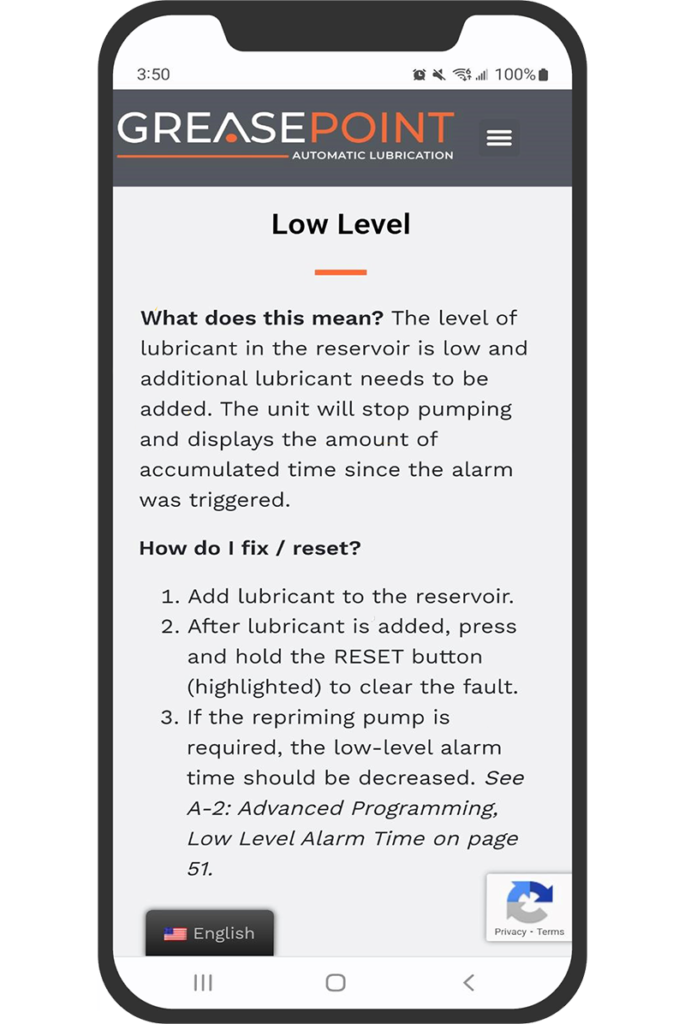

LOW LEVEL

What does this mean? The level of lubricant in the reservoir is low and additional lubricant needs to be added. The unit will stop pumping and displays the amount of accumulated time since the alarm was triggered.

How do I fix / reset?

- Add lubricant to the reservoir.

- After lubricant is added, press and hold the RESET button (highlighted) to clear the fault.

- If the repriming pump is required, the low-level alarm time should be decreased. See A-2: Advanced Programming, Low Level Alarm Time on page 51.

PRESSURE WARNING

What does this mean?

The system fails to relieve pressure in the user-defined amount of time.

The unit will continue to operate for the number of lubrication cycles set by the warning retry parameter. See Advanced Programming, page 49.

If the warning condition clears itself on the next lubrication cycle, the warning is cleared and the unit continues normal operation.

How do I fix / reset?

- Examine the system to determine if you have a plugged or broken line or other component failures i.e., divider valve and injector.

- Press the RESET button (highlighted) to clear the warning.

CYCLE FAULT

What does this mean? The cycle mode indicates a cycle was not completed in the user-defined amount of time.

LED corresponding to the affected sensor input will blink. This could be a warning of one sensor alarm being triggered at the same time.

How do I fix / reset?

- Examine system to determine if you have a plugged or broken line or other component failure i.e., divider valve and injector.

- Press the RESET button (highlighted) to clear the warning.

Not the pump you were looking for?

LEARN MORE ABOUT GRACO

Graco designs and manufactures fluid handling and automatic lubrication equipment specifically for off-road mobile, on-road mobile and in-plant applications.

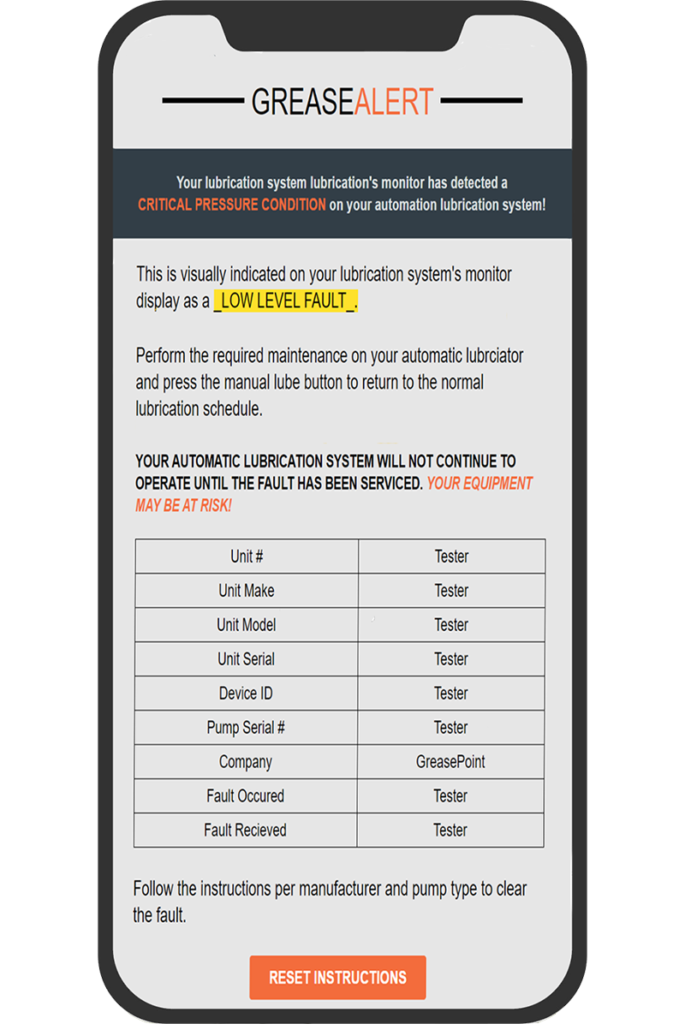

ASK ABOUT REMOTE MONITORING

Compatible with the Graco G3 Pump, GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.