CONSTRUCTION

Provide a steady layer of protection while flushing out contaminants.

- Home

- Industries

- Construction

BROCHURE

We offer a complete line of automatic lubrication systems that increase chassis component life and reduce downtime. Check out highly rated equipment by downloading our flyer.

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

EXTEND THE LIFE OF YOUR EQUIPMENT INVESTMENT

Equipment has to be ready to work when you are. Automatic lubrication systems are built to withstand even the most rugged environments, and to consistently deliver lubrication for optimal performance. Our systems are always on, always working — so your equipment can do the same.

From small wheel loaders to giant off-road trucks, the savings of time and money with an automatic lubrication system grows with each hour of operation. A complete system applies measured lubricant doses to all the various cylinders, pivots, yokes, bearings, arms, pins, and bushings.

As the equipment is in operation, the consistent flow provides a steady layer of protection while flushing out contaminants.

ARE YOU FEELING ANY OF THESE COMMON PAIN POINTS?

Original Equipment Manufacturer (OEM) installed system is not working properly & you’re unable to find support, parts, or service.

There is not enough time and/or manpower to manually lubricate mobile equipment safely & properly.

You are unsure how the system works or if the system is working correctly.

There is not enough grease getting to some points because of safety or where they are located, and we are not sure how to fix this.

CONSTRUCTION REPAIR KITS

GreasePoint offers a Construction Repair Kit that is designed to offer quick, efficient repairs, keeping your operations moving efficiently.

Stay proactive in maintaining your fleet’s efficiency with our fully stocked kit, specifically tailored to meet the rigorous demands of construction sites.

APPLICATIONS

GreasePoint provides automatic lubrication systems and services including installation, training, warranty, and routine inspection and repair for the life of the machine.

WHEEL LOADER

EXCAVATOR

HAUL TRUCKS

PAVERS

GRADERS

SPRAYERS

FREQUENTLY ASKED QUESTIONS

Absolutely, we would be more than happy to come on-site to provide product support and training.

Yes, we can! Our field service technicians come on-site with our fully stocked trailer to install automatic lubrication on new or used equipment.

We install guarding on the working end of the equipment to minimize damage from normal operation.

This varies based on the critical nature of your equipment and costs due to lost production, unplanned downtime, etc. Typically, Return-on-Investment can be seen between 3-15 months.

For a more accurate answer, check out our ROI calculator.

EXTEND THE LIFE OF YOUR EQUIPMENT INVESTMENT

Equipment has to be ready to work when you are. Automatic lubrication systems are built to withstand even the most rugged environments, and to consistently deliver lubrication for optimal performance. Our systems are always on, always working — so your equipment can do the same.

From small wheel loaders to giant off-road trucks, the savings of time and money with an automatic lubrication system grows with each hour of operation. A complete system applies measured lubricant doses to all the various cylinders, pivots, yokes, bearings, arms, pins, and bushings.

As the equipment is in operation, the consistent flow provides a steady layer of protection while flushing out contaminants.

COMMON PAINT POINTS

Original Equipment Manufacturer (OEM) installed system is not working properly & you’re unable to find support, parts, or service.

We do not have enough time and/or manpower to manually lubricate mobile equipment safely & properly.

I am unsure how the system works or if the system is working correctly.

There is not enough grease getting to some points because of safety or where they are located, and we are not sure how to fix this.

APPLICATIONS

GreasePoint provides engineered & protected lubrication solutions and services including installation, training, warranty, and routine inspection and repair for the life of the machine.

WHEEL LOADER

EXCAVATOR

HAUL TRUCKS

PAVERS

GRADERS

SPRAYERS

FREQUENTLY ASKED QUESTIONS

Absolutely, we would be more than happy to come on-site to provide product support and training.

Yes, we can! Our field service technicians come on-site with our fully stocked trailer to install automatic lubrication on new or used equipment.

We install guarding on the working end of the equipment to minimize damage from normal operation.

This varies based on the critical nature of your equipment and costs due to lost production, unplanned downtime, etc. Typically, Return-on-Investment can be seen between 3-15 months.

For a more accurate answer, check out our ROI calculator.

BROCHURE

We offer a complete line of automatic lubrication systems that increase chassis component life and reduce downtime. Check out highly rated equipment by downloading our flyer.

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

LET US LUBE IT

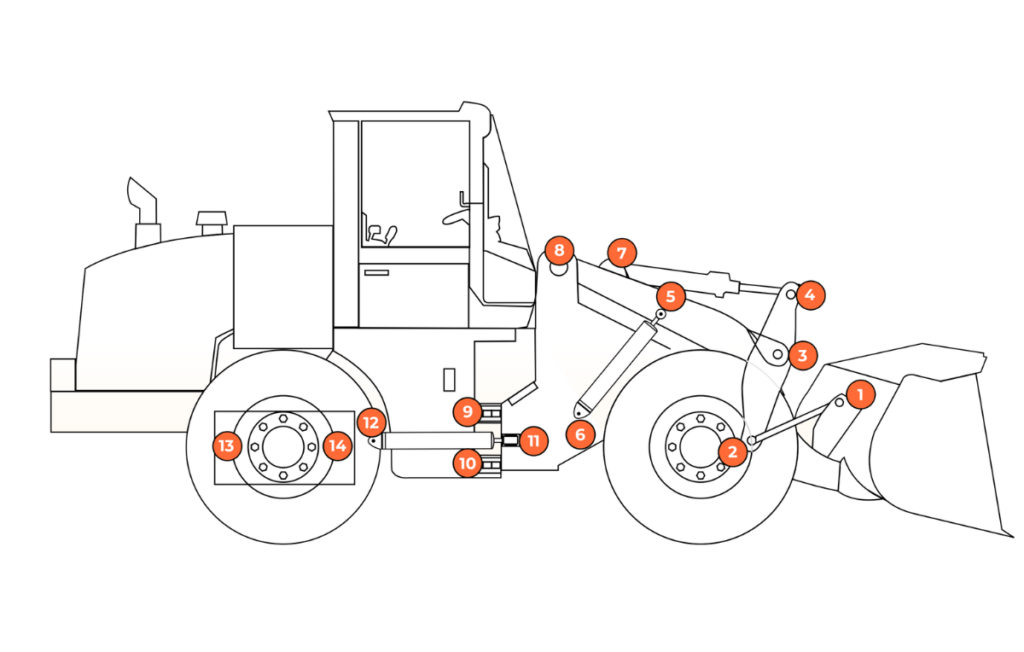

Click on the image to enlarge to see all the points you can automatically lubricate on construction equipment while you work:

- 1. Upper Bucket Pins

- 2. Bucket Link

- 3. Bell Crank Pivot

- 4. Bucket Cylinder Rod End

- 5. Cylinder Rod End

- 6. Cap End

- 7. Bucket Cylinder Cap End

- 8. Boom Pivot

- 9. Upper Articulating Pivot

- 10. Lower Articulating Pivot

- 11. Steering Cylinder Rod End

- 12. Steering Cylinder Cap End

- 13. Rear Axle Cradle

- 14. Rear Axle Nose Bearing

WHAT'S THE RETURN ON INVESTMENT (ROI) OF AN AUTOMATIC LUBRICATION SYSTEM?

An investment in an automatic lubrication system for a typical piece of yellow iron, such as the Caterpillar 320 excavator, has an estimated ROI of as little as nine months. – ©Graco

- York, PA: 888-631-7638

- Charlotte, NC: 704-375-7704

- hello@greasepoint.com

- Service & repair shops in Pennsylvania and North Carolina