Bijur’s Recirculating Oil Systems

- Home

- E-Journal

- Post

Overview

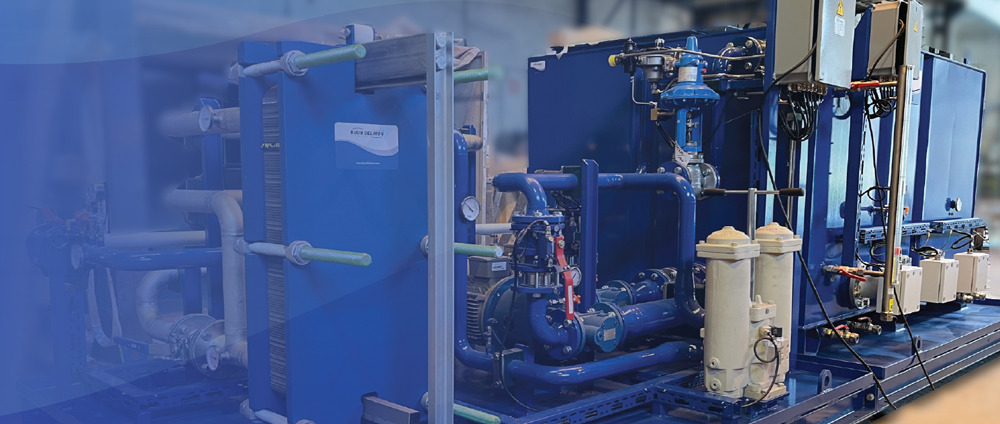

Using Bijur Delimon, GreasePoint works closely with customers to ensure their Oil Circulating Systems achieve the system performance levels required. We pride ourselves on our ability to deliver the complete engineered design solution.

Design of Systems

Bijur Delimon has recognized that the reliability and efficiency of a successful Oil Recirculation System requires it to fulfill the following key functions:

Lubrication: Supplying the appropriate quantity of lubricant of the required viscosity,

temperature and pressure to a bearing or gear train to prevent failure.

Cooling: By maintaining the system oil temperature and flow rate at the required parameters, the heat generated by the motion and load of bearings and gear trains is removed, ensuring that lubrication is provided at the optimum performance level.

Filtration: It is critical to remove contaminants, such as dust, wear particles, water, and other extraneous materials that build up during the operation of bearings and gear trains. The lubricant needs to be continually filtered to the correct cleanliness level prior to being recirculated.

Bijur Delimon Design and Support Teams work closely with customers, component suppliers and lubricant manufacturers to ensure our Oil Recirculation Systems achieve the system performance levels

required

Complete Design Solutions: We pride ourselves on our ability to deliver a complete engineered design solution. Using the latest CAD technology, our innovative design team works together to bring your specifications to life. Through the use of technical drawings, 2D and 3D modeling, our designers ensure all specifications are met with precision without ever compromising the systems efficiency or the manufacturing process. With over 70 years of commercial experience, our dedicated team can cater to any set-up requirements and will guide you every step of the way from concept through to completion.

Standard Product Offering

One electric gear pump draws oil from a reservoir and supplies the oil via check valves through a single or dual basket type filter to the delivery connection.

Standard Units Comprised of:

- Reservoir: Fabricated from mild steel plate, sandblasted, and painted one coat primer with one coat of light grey (RAL7035).

- Reservoir Components: Return and drain connections, level gauge, thermometer, air breather filler and filter.

- Pump & Motor: Positive displacement integral gear type aluminum pump; 1500 rpm motor suitable for 380/440VAC, 3-phase, 50/60Hz supply.

- Oil Filter: 25µ (nominal) stainless steel mesh element; high dirt load capacity; visual/electrical clogging indication; bypass valves. Alternative levels of filtration are available.

- Pressure Relief Valve: Self-operating relief; easily adjustable relief spring pressure.

- Pressure Indication: 63mm gauge; 0-16 bar pressure.

- Check Valve, Pipe & Fittings: Screwed, mild steel.

- Level Switch: 2 position digital level switch.

System Parameters

- Suitable for Mineral Oil

- Applications: Industrial

- Oil Viscosities: Up to and including 1500 cST at 40C

- Oil Flows: 1 to 2000+ LPM

- Maximum Pressure: 20 Bar+

- Voltage: 380/400/440/460/480 V

- Phase: Single & 3 Phase

- Frequency: 50 Hz/ 60 Hz

- Filtration: Simplex & Duplex- 3,6,10,16, & 25 Micron- Absolute and nominal ranges

- Oil Coolers: Shell & Tube, Plate Type, and Air Cooled

- Monitoring: Level, flow, pressure, temperature switches, transmitters, and visual

LIKE WHAT YOU READ? GIVE US A SHARE

RECENT POSTS

SOCIAL MEDIA

SUBSCRIBE TO OUR NEWSLETTER

GET IN TOUCH

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.